This post is also available in: German

- At the IAA 1969 in Frankfurt am Main, Continental presented an ABS for the first time

- Continuing further development ever since – current systems have up to 50 additional functions

- ABS is the central safety system and makes a key contribution to the implementation of Vision Zero, crash-free driving

Frankfurt, September 3, 2019. The mood at the IAA in Frankfurt am Main in the fall of 1969 was excellent. The automobile industry was booming at the time. The technology company Continental also presented a world premiere: Back then, ITT-Teves was presenting the MK I, the first anti-lock brake system (ABS).

The idea of preventing the wheels from locking when a car was braking hard so that the car could continue to be steered had already occurred to vehicle designers in the 1920s. But a solution to the problem only emerged with the development of powerful electronics. Starting in 1965, engineers at Teves (later ITT-Teves) – the company became part of Continental in 1998 – worked on an anti-lock brake system for passenger cars. Starting in the 1970s, integrated circuits based on analog circuit technology were used to regulate brake pressure and in this way prevent the wheels from locking. The system was presented at the IAA 50 years ago in 1969.

Series production was a long time coming, but then there was a technological breakthrough

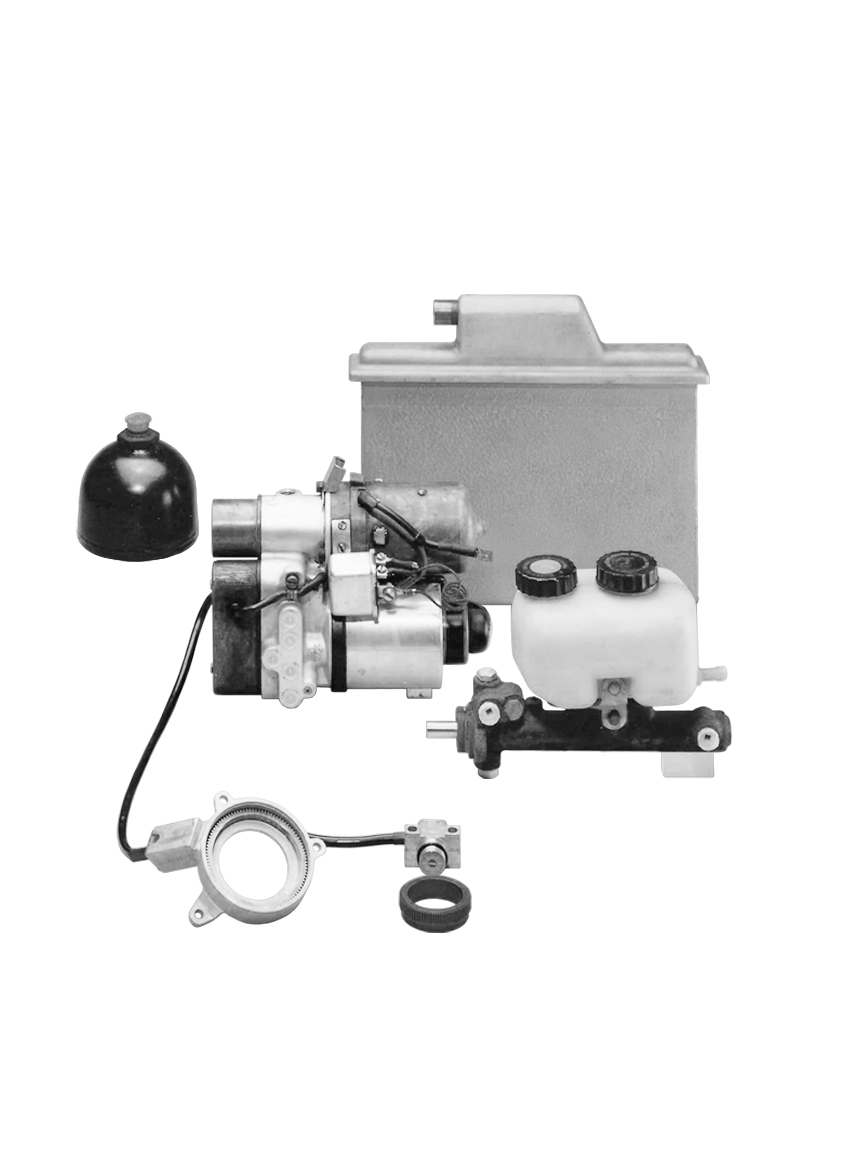

However, the technology was initially only used in 36 test vehicles for the Swedish police. The oil crisis and the subsequent weakening of the economy, which hit the automotive market particularly hard, prevented series production for years. This finally started in 1984, as a technological breakthrough: unlike competing systems that were already on the market, Teves, now part of Continental, launched the MK II, the world’s first microprocessor-controlled ABS for passenger cars on the road. In North America it was available for the Lincoln Continental, while in Europe this safety technology became a standard feature of the Ford Scorpio. Its installation in the factory was another novelty, since at that time ABS was usually only available as an optional feature for a significant surcharge.

Helmut Fennel, who at the time held a key function in promoting the use of microprocessors for ABS, explains the decisive advantage of the technology as follows: “Due to its programmability, our system could be quickly and optimally validated both for braking maneuvers on rough roads, that is, with a high coefficient of friction, and for those on slippery roads, such as on ice in winter. It was also considerably more flexible than other solutions and could therefore be quickly adapted to different vehicle concepts, such as models with front-wheel or all-wheel drive. The microprocessor solution gave us a head start of several years.”

ABS as a central safety system

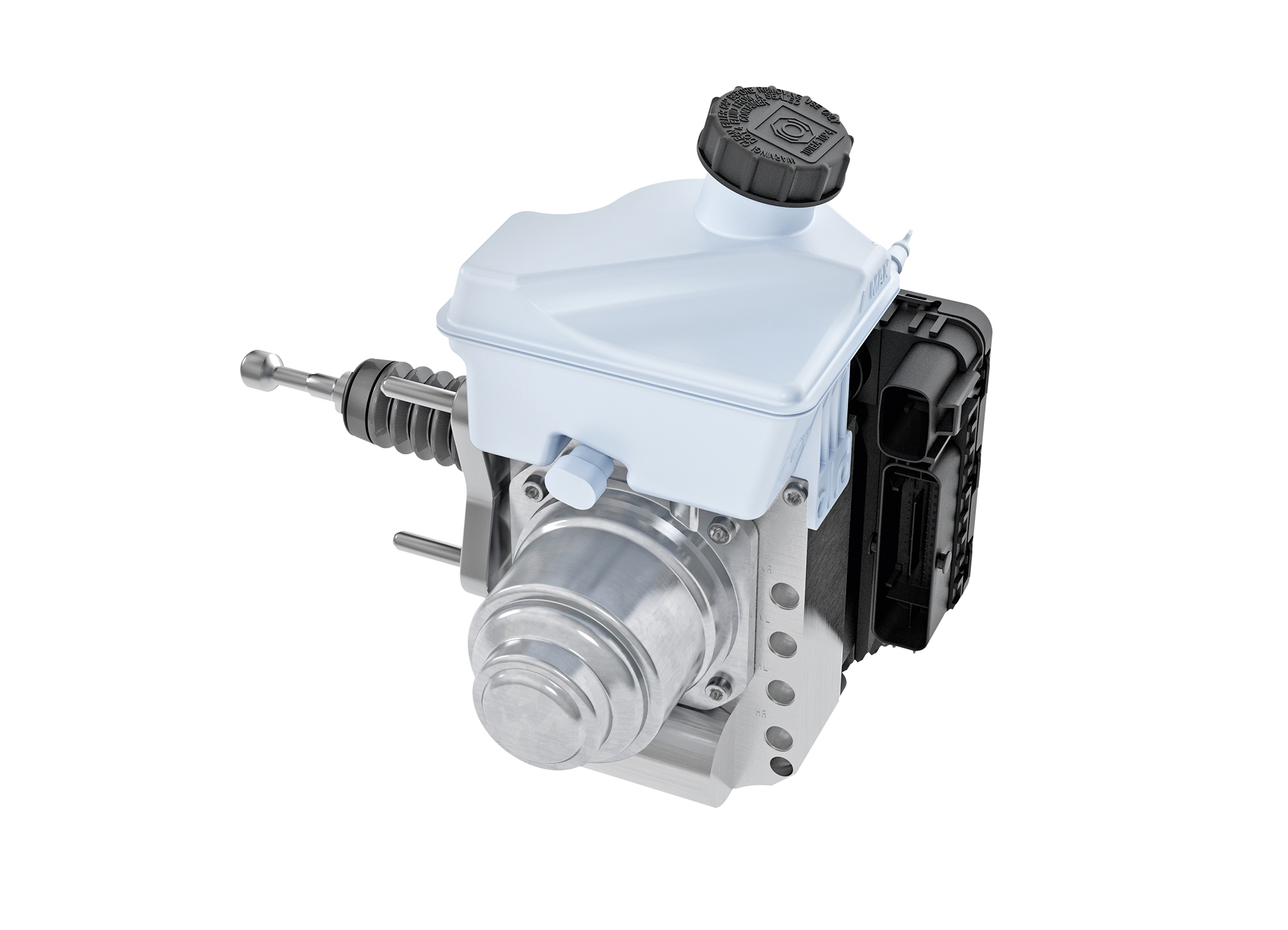

The MK II was the first ABS on the market to combine the brake function, brake booster, hydraulic control and anti-lock brake system into one compact unit. A traction control system (TCS) was also integrated shortly afterward. An important milestone in the development of ABS was the later MK IV system, which went into series production in 1989 and for the first time also included an electronic brake force distribution system, making mechanical-hydraulic components superfluous. Continental’s developers took another developmental leap forward in 1995, when an electronic stability control (ESC) was integrated into the MK 20 system for the first time and furthermore a groundbreaking design was developed. In this new arrangement, which has become the worldwide standard, the engine is located at the top, the valve block in the middle and the electronics below, more or less as the base. Continental anti-lock brake systems are still based on this principle, with the modularity of the equipment variants (ABS, ABS + TCS, ESC) optimally meeting customer requirements.

An ABS today is equipped with up to 50 additional and safety functions, such as the automatic release of the parking brake when starting off, hill start assist or as an important component of adaptive cruise control systems. And all that in just two kilograms and taking up the same amount of space as a single-lens reflex camera (SLR). The first production-ready ABS from Continental was the size of a 5-liter gas can and weighed 11.5 kilograms. Over the past 50 years, ABS has become the universal chassis control system for longitudinal and lateral dynamics, in particular as a result of further developments that eventually led to the ESC. Since the system can individually control the braking force for each wheel, it is indispensable for current and future cross-vehicle control systems. It is also a condition for further safety technologies such as driver assistance systems and enables the next steps towards automated driving.

ABS is the “mother of all chassis control systems,” says Continental developer Jürgen Woywod, who is working on future generations of brake systems. The future of this technology will mainly be determined by software innovations – for more comfort and even more safety. Woywod was also on the team that applied Continental’s ABS technology to motorcycles and put it on the road for the first time in 2006.

ABS technology saves innumerable lives

The introduction of ABS has significantly improved road safety, with other factors such as the safety belt and the introduction of speed limits playing a role alongside the spread of ABS. Since 2004, the system has been required by law for all new cars throughout Europe. Since the introduction of the first systems at the end of the 1970s, the total number of people killed in road traffic in Germany has fallen by 80 percent. The decline in the number of people killed is just as high if we only look at passenger car passengers in Germany during this period. According to GIDAS accident research, 25 percent of all motorcycle accidents in the two-wheel sector can also be prevented by standard ABS. In general, the safety advantage is difficult to overestimate if a technology makes it possible to decelerate a vehicle as much as possible and in a controlled manner in dangerous situations while at the same time ensuring steering control.

ABS – for both passenger cars and motorcycles – therefore makes a significant contribution to the long-term goal of Vision Zero, a future without road traffic crashes. In order to come ever closer to this goal, even after 50 years of ABS Continental is still pressing ahead with the development of this safety system.

Contact for journalists

Miriam Baum

External Communications

Chassis & Safety division

Continental

Phone: +49 69 7603 8492

Email: miriam.baum@continental.com

Sören Pinkow

External Communications

Chassis & Safety division

Continental

Phone: +49 69 7603 8492

Email: soeren.pinkow@continental.com